We design and erect steel superstructures, utilising modern methods of construction that encompass modular components and traditional build solutions.

Working with clients to meet the specific requirements of your project, our expert team create innovative designs that will provide value engineered solutions.

Berry Systems utilises modern design philosophy in a carefully optimised layout to provide the maximum potential for your site.

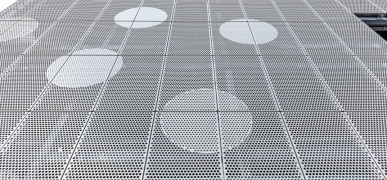

Our catalogue of products, from barriers to facades, can all be integrated.

Our systems meet all relevant building regulations and standards and can cater to sites that are awkwardly shaped or have restricted access.

The flexibility of our designs enables us to incorporate ramps for optimised traffic flow and stairs for pedestrian safety, without compromising existing facilities.

CP-DAS enables us to project manage your project from conception to completion through a devised strategy to enable efficient installation, while utilising resources that are kind to your budget.

The planning and design of an installation is typically in three steps:

Step 1 – Concept:

We develop and produce the initial concept from satellite photography if you don’t have current CAD plans.

Step 2 – CAD Drawings:

We will then produce a fully detailed CAD plan with elevations. This is usually deemed to be sufficient for planning applications.

Step 3 – Finalised Design:

A full ground investigations report follows, the design to be finalised and 3D site modelling to be produced.

Our car parks have been designed incorporating many modern methods of construction.

- Automated parking facilities

- EV charge points and solar roof canopies

- Latest design software & Tekla modelling

- Access lanes identified by colour of deck coating

- Modular ramps and stairs for rapid attachment to parking modules

- Optional speed-build cladding where required

Planning – we meticulously plan the initial concept of the project to cater for all requirements.

Design – we create a detailed design using CAD and 3D site modelling.

Build – our expert installation teams utilise speed build technology to erect your project.

Traditional build car parks involve utilising a steel frame designed in order to install a composite steel decking and concrete slab.

Our in-house designers are able to design structures with large free spans and flexible layouts for more complex sites.

Benefits of traditional build car parks:

- Cost efficient method of construction

- Adaptable layouts for tighter sites

- Large free spans

- High volume spaces can be achieved with ease

All our steel frames are galvanised in accordance with BS EN ISO 1461-1. However, they can be adapted to include a painted finish for enhanced lifespans or to suit visual aesthetics.

TopDeck car parks have been designed incorporating many modern methods of construction for an efficient erection, enabling installation to be completed in days rather than months.

Benefits of TopDeck:

- No foundations necessary if site conditions are suitable

- Screw Pile foundations of rapid installation if foundations are required

- Automatic lane markings – rubber seals between modules visually delineate parking bays

- Modular design for fast erection

- Pre-finished anti-skid decks

- Minimal disruption due to off-site construction

In theory, there is no minimum or maximum number of parking spaces in a TopDeck car park, but typically capacity is between 70 and 700. Standard modules are 16 metres long, comprising two opposing parking bays at 2.4m x 4.8m, separated by a 6m access way.

Pre-assembled

Off-site preparation and assembly means reduced construction time.

Adaptable

Our expert team will work closely with you on all aspects of your project to ensure success.

Rainwater management

Installed to provide a 1:50 gradient for rainwater run-off, the TopDeck surface is a resin based slip-resistant waterproofing system.

Many elements of TopDeck are built at our manufacturing facilities. The water resistant, anti-skid, grit-coat surface is also factory applied and safety barriers are pre-installed. Hinged columns are incorporated where required for structural integrity with maximum accessibility. Quality control is ensured by manufacturing systems to BS EN ISO 9002 and galvanising to BS EN ISO 1461:1994.

Units are delivered to site in a ‘flat pack’ state for rapid assembly as each unit is securely attached to the previous one. Hinged columns are swung into place and locked down.

Off-site construction

- Pre-fitted plug and play electrics

- Pre-finished anti-skid decks

- Pre-fitted integral safety barriers and tested to BS 6399

- No wet trades needed on site

- Modular design for fast, consistent erection