Overview:

Berry Systems recently completed a Vehicle Restraint System (VRS) project for a large-scale supermarket chain, located at their major distribution centre in Luton. This case study highlights the challenges, solutions, and outcomes of the project, showcasing Berry Systems’ expertise in providing tailored safety solutions for complex environments.

The Challenge:

The distribution centre in Luton required a robust and reliable VRS to ensure the safety of its operations, particularly on the mezzanine floor. The key challenges included:

• High Impact Rating Requirements: The VRS needed to withstand significant impacts, with a requirement for a 300kN impact rating to ensure maximum safety.

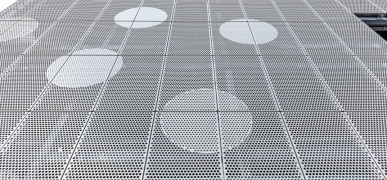

• Integrated Safety Features: The solution needed to integrate seamlessly with handrails and an anti-climb mesh system to prevent unauthorised access and enhance overall safety.

• Custom Design Specifications: The anti-climb mesh had to be customised with extensions to create gaps of less than 30mm, ensuring compliance with stringent safety regulations.

The Solution:

Berry Systems designed and installed a comprehensive VRS solution using their advanced RBI spring steel posts with flexbeam technology. The key components of the solution included:

• RBI Spring Steel Posts: Known for their flexibility and strength, these posts provide superior impact absorption, reducing the risk of damage to vehicles and infrastructure.

• Flexbeam: This component adds an additional layer of protection, ensuring that the VRS can withstand high-impact forces while maintaining structural integrity.

• Integrated Handrail and Anti-Climb Mesh System: To enhance safety, Berry Systems integrated a handrail with a custom-designed anti-climb mesh system. The mesh extensions ensured that gaps were less than 30mm, preventing unauthorised access and meeting all safety standards.

Implementation:

The implementation process involved close collaboration with the client to ensure all requirements were met. Key steps included:

• Site Assessment and Planning: Berry Systems conducted a thorough site assessment to understand the specific needs and challenges of the Luton distribution centre.

• Custom Design and Fabrication: The VRS components were custom designed and fabricated to meet the exact specifications, ensuring a perfect fit and optimal performance.

• Installation and Integration: The installation was carried out by Berry Systems’ experienced team, ensuring seamless integration with existing infrastructure and minimal disruption to operations.

The Result:

The completed VRS installation at the distribution centre delivered exceptional performance and safety enhancements, including:

• High Impact Protection: The RBI spring steel posts with flexbeam technology provided the required 300kN impact rating, ensuring robust protection against vehicle impacts.

• Enhanced Safety Features: The integrated handrail and custom anti-climb mesh system enhanced overall safety, preventing unauthorised access and reducing the risk of accidents.

• Compliance and Reliability: The solution met all relevant safety standards and regulations, providing the client with a reliable and compliant VRS system.

Conclusion:

The successful completion of the VRS project demonstrates Berry Systems capability to deliver high-performance, customised safety solutions. The project not only met the stringent safety requirements but also showcased Berry Systems’ commitment to quality and innovation in VRS technology.For more information about Berry Systems and their range of VRS solutions, please visit www.berrysystems.co.uk or contact us at info@berrysystems.co.uk.

Why Berry Systems:

• Over 50 years as an expert industrial solutions provider, offering a wide range of products and services including world class sustainable Car Parks, Vehicle Restraint Systems, Cladding and Facades

• Industry leading engineering and project management teams

• Continuous innovation – always keeping customers at the forefront of technological advances to ensure products and services meet the challenges of continuous development

• Commitment to quality through the membership and accreditation of major industry organisations such as The Building Safety Group, Acclaim Accreditation and as an accredited contractor for CHAS.