Synopsis:

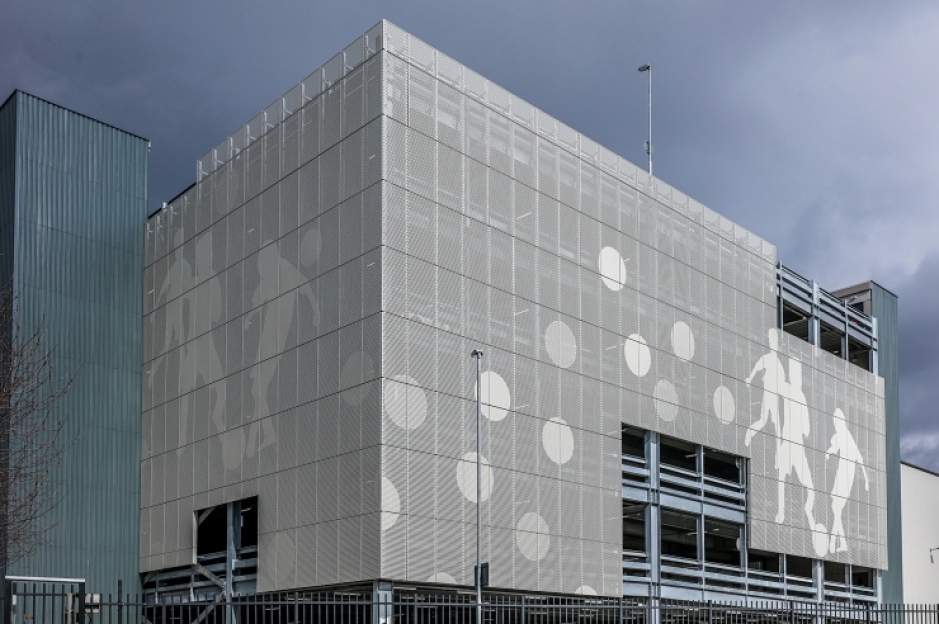

Amazon recently invested in a multi-storey car park at their warehouse in Neasden to cater for the demand for additional staff parking on site, as well as to improve the efficiency of their deliveries. Due to the ever-increasing demand for next day deliveries, Amazon decided to install a unique van parking deck that allows lorries to park up and then be loaded all within the same parking structure.

The new facility provides their delivery vans and lorries with electric charging points as part of the increased drive for more sustainability in their approach to goods delivery.

Products installed:

- Expanded Mesh

- Perforated Panels

- Graphic Imagery Perforated Panels

- Trapezoidal Sheeting

Amazon Car Park, Neasden:

Berry Systems designed and installed a new van parking deck for a newly built multi-storey car park at the Amazon warehouse in Neasden, with a range of products used to meet safety, weather and aesthetical requirements.

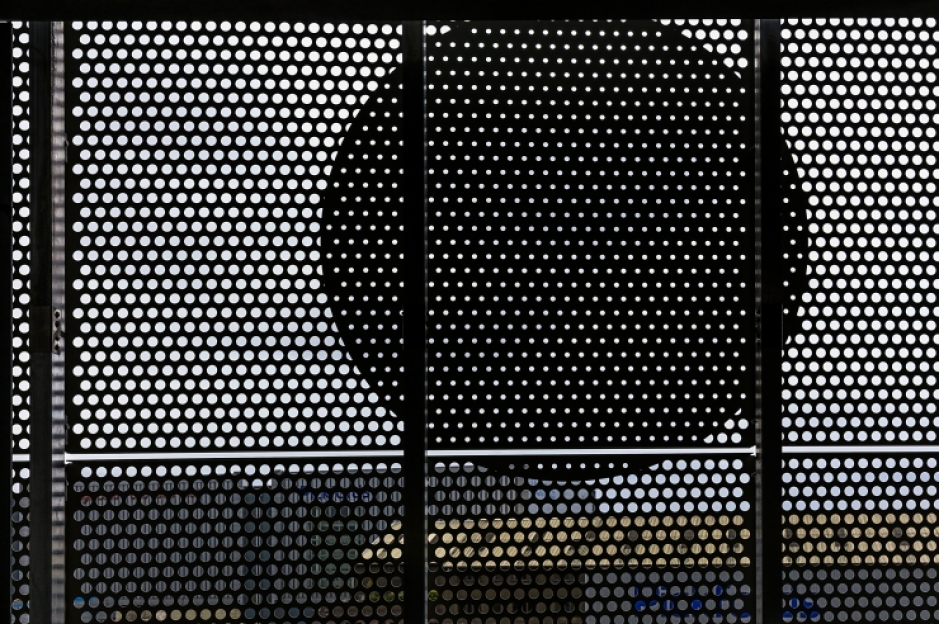

With the car park’s proximity to Wembley Stadium, the architect wanted imagery features of children playing football to pay homage to the iconic landmark and to fit in with nearby Wembley car parks. Berry Systems were involved early in the design process to specify the right products to ensure these demands were met.

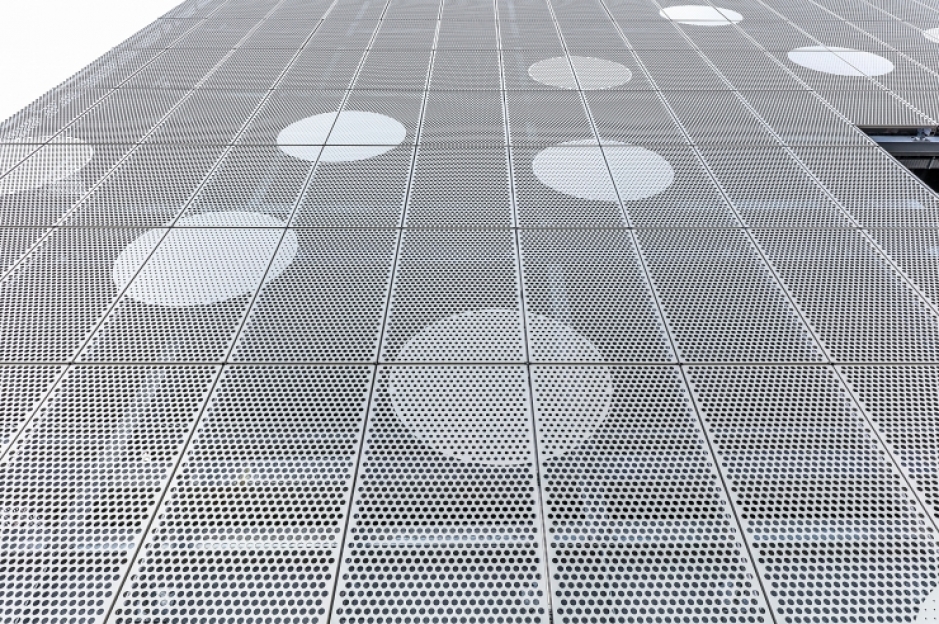

Full-sized samples were produced and approved before manufacturing commenced to ensure standard of quality and designs were met.

All the products installed had to meet the usual safety and weather regulations, and Berry Systems used their car park expertise to be able to recommend the most suitable products for this project, combining style, safety and performance.

Key highlights:

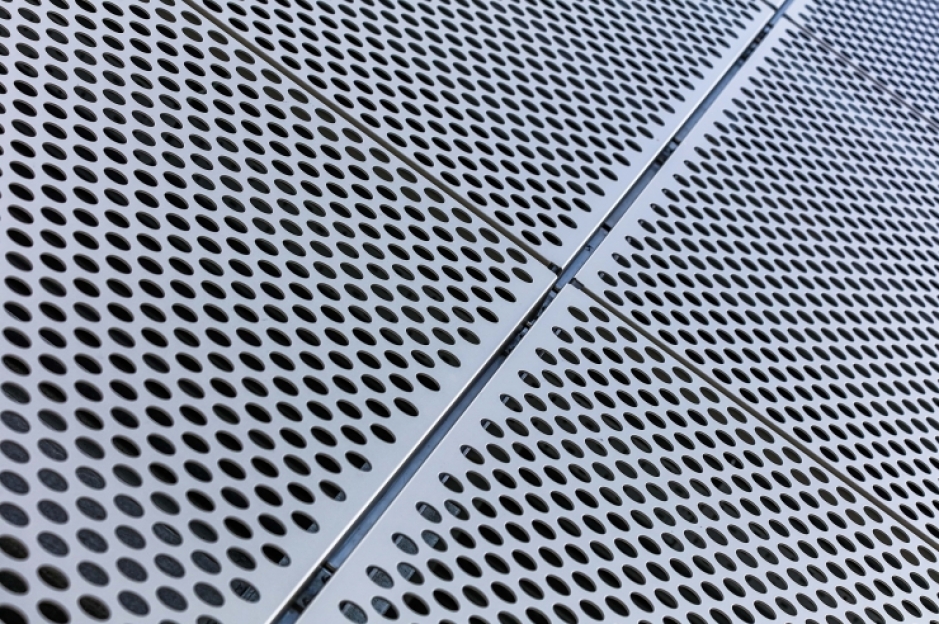

Working early in the design process, Berry Systems were able to undertake free are calculations and use their expertise to specify open area mesh and perforated panels.

Nearly 5000 sqm of cladding delivered in 6 weeks allowed the project to stick to precise timing demands.

Graphic imagery comprising of individually designed bespoke patterns and production of full-sized samples helped ensure the architectural requirements of the project were met.

The use of hook-on cassettes using our Atlas carrier system allowed for easy installation.

Specification:

- Ash and Lacy Vision Webb expanded mesh

- Standard perforated panels with 3mm gauge aluminium

- Bespoke “Imagery” perforated panels with 3mm gauge aluminium

- Firth Steels N1000C trapezoidal sheeting to stair cores